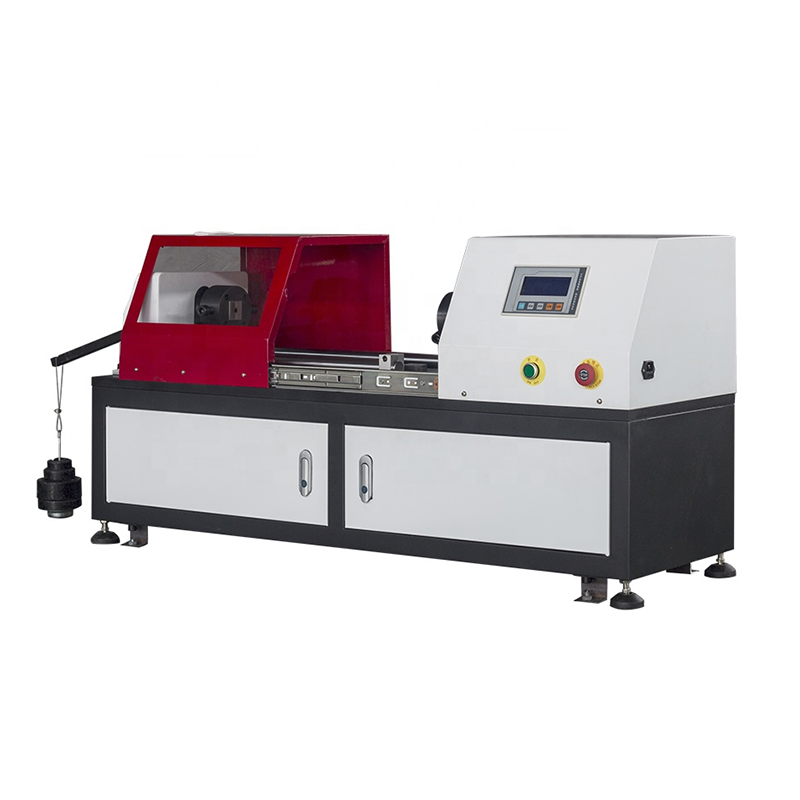

China wholesale Notch Making Machine - CYLSN-1000E Microcomputer Controlled High Strength Bolt Testing Machine – Chengyu Detail:

CYLSN-1000E Introduction

1.1 Application:The detector is based on GB/T 2611-2007 “General Technical Requirements for Testing Machines”, JB/T 9370-2015 “Technical Conditions for Torsional Testing Machines”, JJG 139-2014 “Testing Machine Verification Regulations” and other commonly used national and industry testing machine standards . At the same time, refer to GB/T1231-2006 “Technical Conditions for Large Hexagon Bolts and Large Hexagon Nuts for Steel Structures”, GB/T16823.1-2010 “Fastener Torque-Clamping Force Test”, GB50205-2001 “Construction Quality of Steel Structure Engineering” “Acceptance Specification”, GB/T 32076.2-2015 “Preload High Strength Bolted Structural Connection Pair”, EN 14399.2-2005 “Preload High Strength Structural Bolt Assemblies. Part 2: Preload Suitability Test”, ASTM A325M-2009 “Standard Specification for Heat Treated Steel Structural Bolts with Heat Treated Minimum Tensile Strength of 830Mpa”, ASTM F3215/F3125M-15a “Heat Treated Minimum Tensile Strength of 120 ksi (830 MPa) and 150 ksi (1040 MPa) Standard Specification for Steel and Alloy Steel High Strength Structural Bolts with Inch and Metric Dimensions “AS/NZS1252:1996 “High Strength Bolts for Construction (Bolts with Nuts & Washers)” NB/T31082-2016 “Wind Turbine Towers It can be designed and manufactured according to relevant requirements such as High-strength Bolt Connection Pairs for Racks. It can detect, display and print the axial force, torque and torque coefficient of hexagonal head and double-head high-strength bolt connection pairs. When the axial force reaches the value specified in the standard, the detector will beep and record the peak value of the detection data. After the equipment stays for 1 second, it will automatically reverse and loosen the sample. At the same time, the detector will automatically calculate the torque according to the detected axial force and torque. The coefficient is automatically displayed; when a group of tests is completed, the detector automatically calculates the average axial force, average torque, average torque coefficient, standard deviation and coefficient of variation of N specimens;

1.2 Technical parameters and control methods:

1.2.1 Voltage: control system 220V AC; motor AC 380V

1.2.2 Total motor power: 5.0KW

1.2.3 Output speed: 0.1-4r/min

1.2.4 Axial force detection range: 100-1000kN

1.2.5 Torque detection range: 100-5000Nm

1.2.6 Large hexagon bolt specifications: M10M12M16M20M24M27M30M36M39

1.2.7 Bolt length: 30mm—350mm (≥2.5d)

1.2.8 Test accuracy: axial force ±1.0% torque ±1.0%

1.2.9 Torsion angle measurement range 0-1000° (unlimited)

1.2.10 Relative error of indication value of torsion angle ±1%

1.2.11 Relative error of torsion speed Within ±1.0% of the set value

1.2.12 Weight: about 2000kg

1.2.13 Customized measurement and control system*1(meet EN14399-2:2005(E) standard)

1.3 Control method:

1.3.1 The equipment can be controlled by any method such as setting the axial force, setting the torque, and setting the angle of rotation.

1.3.2 It has the function of setting initial torque→first target angle→second target angle, and then testing the torque value and axial force value under each target.

Configuration list

|

No. |

Items |

Unit |

Qty. |

|

1 |

Test host (including high-precision 1000kN axial force sensor and 5000NM torque sensor) |

set |

1 |

|

2 |

3.0KW imported servo motor kimono drive system |

set |

1 |

|

3 |

Microcomputer-controlled high-strength bolt test special controller |

set |

1 |

|

4 |

Lenovo computer mainframe and LCD monitor |

set |

1 |

|

5 |

Nut sleeve |

set |

1(total 10 pieces) |

|

6 |

Bolt outer plate or outer plate M10M12M16M20M22M24M27M30M36 M39 |

set |

1(total 10 pieces) |

|

7 |

Bolt inner baffle M10M12M16M20M22M24M27M30M36 M39 |

set |

1(total 10 pieces) |

|

8 |

Anti-rotation board M10M12M16M20M22M24M27M30M36 M39 |

set |

1(total 10 pieces) |

|

9 |

Front and rear automatic adjustment device of mobile base (including motor, reducer and high-precision ball screw) |

set |

1 |

|

10 |

Full protection safety push-pull metal shield (this is optional) |

set |

1 |

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for China wholesale Notch Making Machine - CYLSN-1000E Microcomputer Controlled High Strength Bolt Testing Machine – Chengyu , The product will supply to all over the world, such as: Uzbekistan, Birmingham, Liverpool, With a state-of-the-art comprehensive marketing feedback system and 300 skilled workers' hard work, our company has developed all kinds of products ranging from high class, medium class to low class. This whole selection of fine products offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer good OEM services to many famous brands.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.