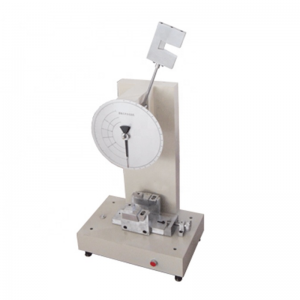

Application

DWC Series Temperature Chamber is designed according to the standard of 'Charpy Notch Impact Test Method for Metal Materials' and adopts compressor cooling technology, which is made up of two sections (Low temperature grade and high temperature grade).

It utilizes the heat balance principle and cycle stirring method to realize the constant temperature cooling to impact specimen with the reliable performance.

Key Features

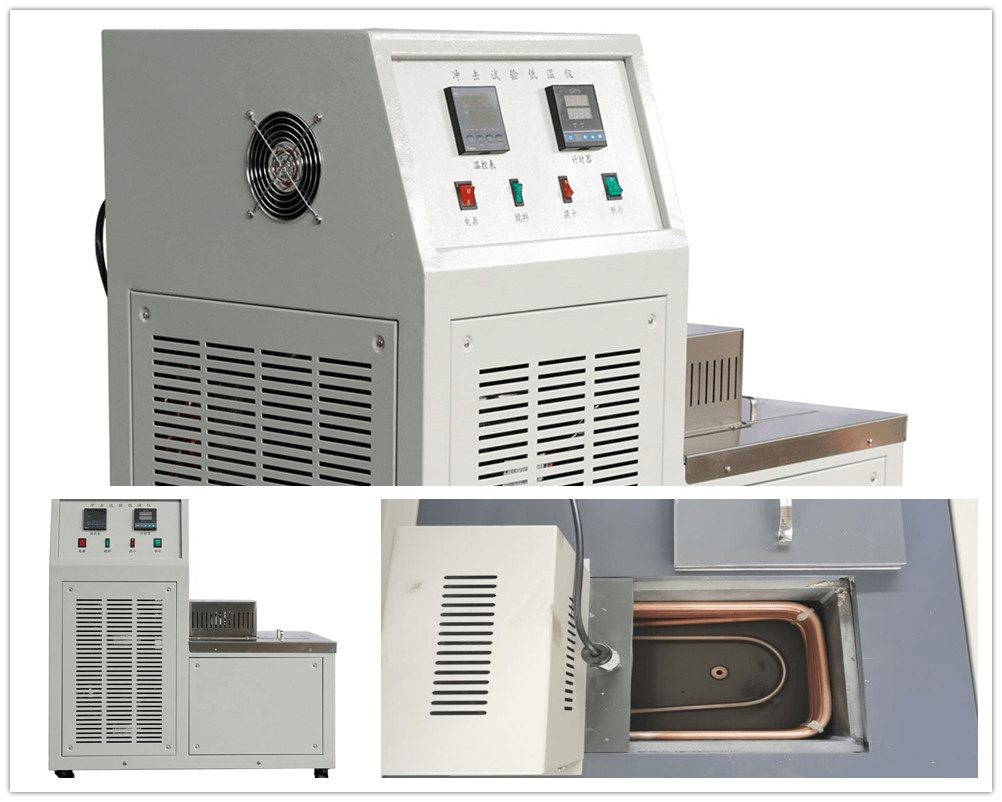

1. Imported compressor, DANFUS valve, imported evaporation-condensation machine;

2. Controlled by intelligent instrument, digital presentation temperature value, automatic control temperature,automatic time and alarm.

3. High security, refrigerate fast, large volume.

Specification

|

Model |

DWC-40 |

DWC-60 |

DWC-80 |

|

Control range |

Room temperature~-40°(Room temperature 0-25°) |

Room temperature~-80°(Room temperature 0-25°) |

Room temperature~-80°(Room temperature 0-25°) |

|

Constant temperature accuracy |

<±0.5℃ |

<±0.5℃ |

<±0.5℃ |

|

Cooling speed |

0℃ ~ -30℃ 1.2℃/min -30℃ ~ -40℃ 1℃/min |

0℃ ~ -30℃ 1.2℃/min -30℃ ~ -40℃ 1℃/min -40℃ ~ -60℃ 0.7℃/min |

0℃ ~ -30℃ 1.2℃/min -30℃ ~ -40℃ 1℃/min -40℃ ~ -60℃ 0.7℃/min 60℃ ~ -80℃ 0.5℃/min |

|

Cold room volume |

160*140*100mm |

160*140*100mm |

160*140*100mm |

|

Cooling medium |

99% ethanol |

99% ethanol |

99% ethanol |

|

Sample can be loaded |

>60 |

>60 |

>60 |

|

Stirring motor |

8W |

8W |

8W |

|

Machine weight |

70Kg |

80Kg |

80Kg |

|

Rated current |

AC 220V 50Hz,1KV |

AC 220V 50Hz,1.5KV |

AC 220V 50Hz,1.5KV |

Standard

ASTM E23-02a, EN10045, ISO148, ISO083, DIN 50115, GB229-2007

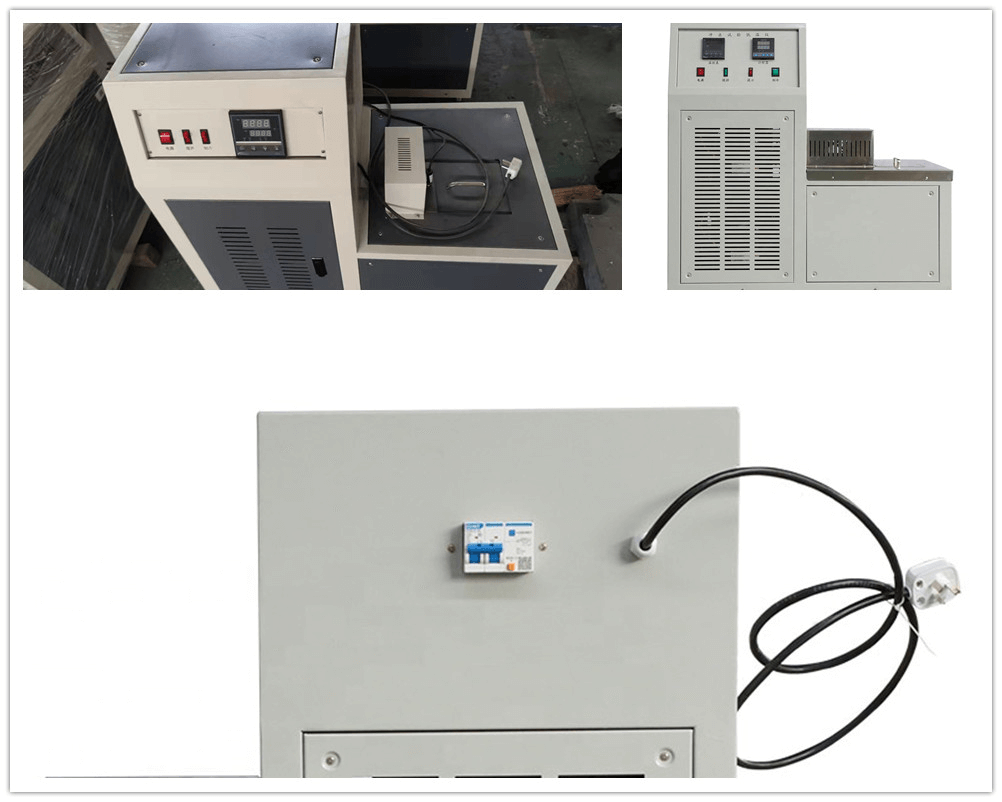

Real photos