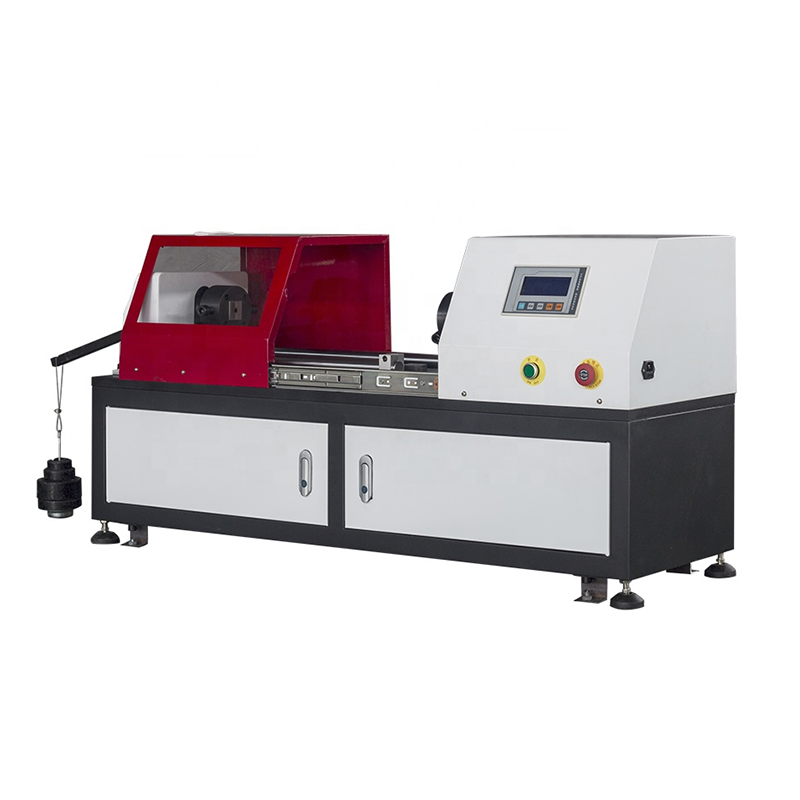

Application Field

ER-10 wire torsion winding test machine is a new type of wire torsion winding test machine. The machine is a horizontal structure and consists of loading, transmission, winding, afterburning, tracking, and other parts. It is suitable for a nominal diameter of Φ1. -Testing of the torsion and winding performance of Φ10mm steel wire; rotation speed: 15, 20, 30, 60 rpm adjustable. It mainly measures the ability of the wire to withstand plastic deformation in one-way, two-way torsion or winding, and shows the surface and internal defects of the wire.

Structure and Characteristics

1. Main machine: adopts horizontal structure, and the main structure adopts frame structure to ensure the rigidity of the whole machine. The mandrel is made of high-quality alloy structural steel with smooth surface and high rigidity to ensure its service life.

2. Drive system: motor drive, large rotating torque, uniform loading, stable and no impact.

3. Transmission system: use precision reducer to ensure the uniformity, stability and high transmission accuracy of the transmission.

According to the Standard

It conforms to standards of ASTM A938, ISO 7800: 2003, GB/T 239-1998, GB 10128 and others equivalent.

| Model |

ER-10 |

| The maximum distance between the two chucks |

500mm |

| Rotation speed |

15, 20, 30, 60 |

| Jaw hardness |

HRC55~65 |

| Working noise of the testing machine |

<70db |

| Wire diameter |

Φ1-Φ10mm |

| Winding speed |

15/20/30/60rpm |

| Effective working length of mandrel |

100mm |

| Power supply |

380V, 50Hz |

| Winding direction |

forward or reverse |