Application Field

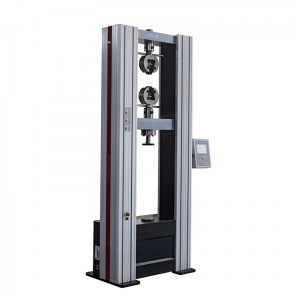

The high low temperature tensile testing machine is used to test the material tensile strength under different temperature, when doing normal temperature test, can remove the temperature cabinet.

Specification of UTM

|

Model |

WDG-100E (10E-100E optional) |

WDG-150E |

|

Maximum test force |

100KN /10 tons (optional 1 ton -10 tons) |

150KN 15 tons |

|

Test machine level |

0.5 level |

0.5 level |

|

Test force measurement range |

2%~100%FS |

2%~100%FS |

|

Relative error of test force indication |

Within ±1% |

Within ±1% |

|

Relative error of beam displacement indication |

Within ±1 |

Within ±1 |

|

Displacement resolution |

0.0001mm |

0.0001mm |

|

Beam speed adjustment range |

0.05~1000 mm/min (arbitrarily adjusted) |

0.05~1000 mm/min (arbitrarily adjusted) |

|

Relative error of beam speed |

Within ±1% of the set value |

Within ±1% of the set value |

|

Effective stretching space |

900mm standard model (can be customized as required) |

900mm standard model (can be customized as required) |

|

Effective test width |

500mm standard model (can be customized according to requirements) |

500mm standard model (can be customized according to requirements) |

|

Dimensions |

720×520×1850mm |

820×520×1850mm |

|

Servo motor control |

1KW |

1.5KW |

|

power supply |

220V±10%; 50HZ; 1KW |

220V±10%; 50HZ; 1.5KW |

|

Machine weight |

550Kg |

650Kg |

|

Main configuration: 1. Industrial computer 2. A4 printer 3. A set of high temperature furnace 5. A set of high temperature rod |

||

Specification of High and low temperature tank

|

Model |

HGD—45 |

|

Bore size |

Inner chamber size: (D×W×H mm): about 240×400×580 55L (customizable) |

|

Temperature range |

Dimensions: (D×W×H mm) about 1500×380×1100 (customizable) |

|

Temperature control accuracy |

Low temperature -70℃~high temperature 350℃ (customizable) |

|

Temperature uniformity |

±2ºC; |

|

Heating rate |

±2ºC |

|

Observation hole |

3~4℃/min; |

|

Temperature control |

Hollow electric heating glass observation window (when the temperature is 350 degrees, the observation window is surrounded by stainless steel) |

|

Outer wall material |

PID automatic temperature control; |

|

Inner wall material |

Spraying with cold rolled iron plate; |

|

Insulation material |

Use stainless steel plate material; |

|

Air conditioning system |

a Temperature control: PID control; b Air circulation device: centrifugal fan; c Heating method: nickel-chromium electric heater, forced ventilation and internal circulation temperature adjustment; d Air cooling method: mechanical compression refrigeration; e Temperature measurement sensor: platinum resistance; f Refrigeration compressor: dual compressor refrigeration;

|

|

Safety protection device |

Power overload and short circuit protection; a The refrigeration compressor lacks phase protection; b Grounding protection; c Over-temperature protection; d Refrigerator high and low pressure protection. |

|

Tightness and reliability |

The cooling system pipeline should be welded and sealed reliably; |

|

Flashlight |

1 (moisture-proof, explosion-proof, placed in appropriate position, external control switch); |

|

Both the door frame and the edge of the door panel are equipped with electric heating devices to prevent condensation or frost during the low temperature test; |

|

|

Power supply |

AC 220V,50Hz 5.2KW |

Key Features

1.Computer + Software control and display 6 kinds test curves: Force-displacement, force-deformation, stress-displacement, stress-deformation,force-time,displacement-time

2.Can be installed extensometer to test deformation of rubber or metal material

3.Can do high low temperature test by high low temperature oven and furnace

4.Can be installed all kinds of test fixtures, manual / hydraulic / pneumatic fixtures

5.Can be customized height, width, and follow any test standard or customer request

6.Also have Digital Display Type.

Standard

ASTM, ISO, DIN, GB and other international standards.