Application

HB-3000B Brinell hardness tester is a table hardness tester, suitable for annealing and normalizing of workpieces, casting parts, non-ferrous metals and soft parts or unhardened steel parts and so on Brinell hardness. The machine has firm structure, good rigidity, accuracy, reliability, durability and high test efficiency. The accuracy is in line with GB/T231.2, ISO6506-2 and American ASTM E10. It is applicable to metrology, metal metallurgy, chemical industry, machinery manufacturing, industry and scientific research institutions in Colleges and universities.

Key Features

1. Equipped Brinell, Rockwell, Vickers test methods;

2. Touch-screen interface, easy to operate

3. Close loop, with high accuracy load cell, no need install weights;

4. Test force automatic correction, each file is automatically compensated force, improve the accuracy of the force a number of levels;

5. According to GB / ASTM hardness automatic conversion;

6. Rockwell automatically correct curvature radius;

7. Set a password to protect setup parameters, more samples and testing information;

8. Measuring U disk to save data to EXCEL format for easy editing and processing.

9. Modular design for easy maintenance.

Specification

|

specification |

Model |

|

|

HB-3000B |

||

|

Measuring range |

8-650HBW |

· |

|

Test force |

187.5kgf(1839N)、250kgf(2452N)、500kgf(4903N)、 750kgf(7355N)、1000kgf(9807N)、3000kgf(29420N) |

· |

|

Loading method |

Weight loading |

· |

|

Carbide ball diameter |

φ2.5mm 、 φ5mm 、 φ10mm |

· |

|

Maximum allowable height of sample |

230mm |

· |

|

Distance from center of indenter to machine wall |

120mm |

· |

|

Test force retention time |

1—99 S |

· |

|

National standard measurement error |

±3% |

· |

|

power supply |

AC220V 50/60HZ |

· |

|

Dimensions |

700*268*842mm |

· |

|

net weight |

187kg |

· |

|

Gross weight |

210kg |

· |

Standard

GB/T231.2, ISO6506-2 and American ASTM E10

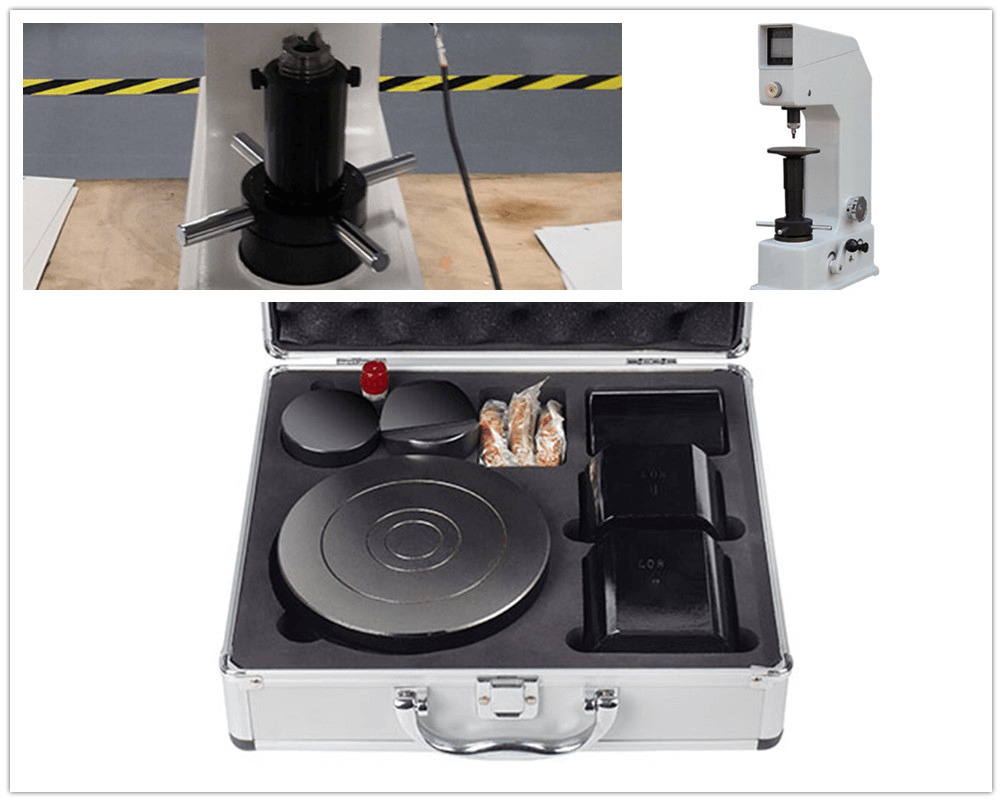

Real photos