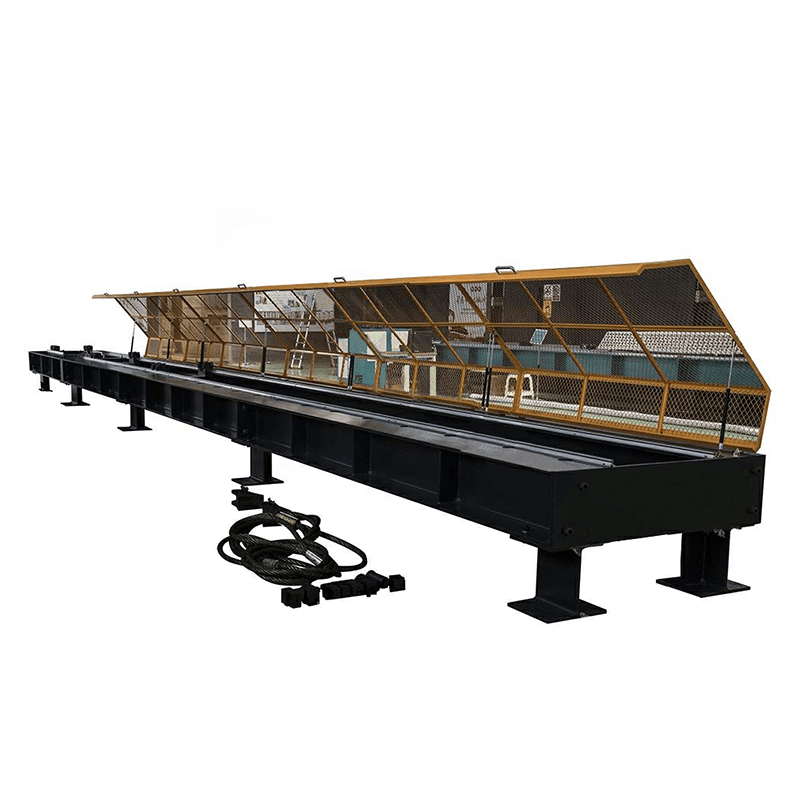

Hot New Products Universal Tensile Strength Testing Machine - WEW-1000D Hydraulic Universal Testing Machine – Chengyu Detail:

Application Field

This series universal testing machine UTM designed of PC display and manual drive hydraulic loading system, main engine controller separately fixed. It has the characteristics of operation amenity, working steady, high accuracy and loading steady. It is used to stretch, compress, curve and cut metal cement, concrete, plastics and so on.

Key Features

1 Fuel tank is mounted under the host, tensile test space is located above the host, compression, bending, shearing test space is located under the host, means between beam and worktable.

2 The structure is designed with solid four column and two screw, the whole machine has strong stability.

3 The host is designed all-inclusively to ensure its super strong stiffness so that it can resist micro-deformation when it is loading.

4 Middle beam adopts adjustable gap screw-nut mechanism, eliminating the gap and improving the measurement performance.

5 Fuel tank adopts gap sealed, improving the measurement accuracy and also extending service lifetime.

6 When the test force exceeds 2%-5% of the maximum test force of each file, overload protection, it will stop.

7 When the piston rises to the upper limit position, travel protection, pump motor will stop.

According to the Standard

It meets the requirements of the national standard GB/T228.1-2010 “Metal Material Tensile Test Method at Room Temperature”, GB/T7314-2005 “Metal Compression Test standards. It can meet the requirements of users and the standards provided.

Transmission System

The lifting and lowering of the lower crossbeam adopts a motor driven by a reducer, a chain transmission mechanism, and a screw pair to realize the adjustment of the tension and compression space.

Hydraulic System

The hydraulic oil in the oil tank is driven by the motor to drive the high-pressure pump into the oil circuit, flows through the one-way valve, high-pressure oil filter, differential pressure valve group, and servo valve, and enters the oil cylinder. The computer sends a control signal to the servo valve to control the opening and direction of the servo valve, thereby controlling the flow into the cylinder, and realizing the control of constant velocity test force and constant velocity displacement.

|

Model |

WEW-1000B |

WEW-1000D |

|

Structure |

2 Columns |

4 Columns |

|

2 Screws |

2 Screws |

|

|

Max.Load Force |

1000kn |

|

|

Test Range |

2%-100%FS |

|

|

Displacement Resolution(mm) |

0.01 |

|

|

Clamping Method |

Manual clamping or Hydraulic clamping |

|

|

Piston Stroke(Customizable)(mm) |

200 |

|

|

Tensile Space(mm) |

670 |

|

|

Compression Space(mm) |

600 |

|

|

Round Specimen Clamping Range(mm) |

13-50 |

|

|

Flat Specimen Clamping Range(mm) |

0-50 |

|

|

Compression Plate(mm) |

Φ200 |

|

Related Product Guide:

Our mission will be to grow to be an innovative supplier of high-tech digital and communication devices by giving worth added design and style, world-class production, and service capabilities for Hot New Products Universal Tensile Strength Testing Machine - WEW-1000D Hydraulic Universal Testing Machine – Chengyu , The product will supply to all over the world, such as: Ireland, Kuala Lumpur, Gambia, We follow up the career and aspiration of our elder generation, and we're eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have now a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.