Overview

HVW-30Z computer type automatic turret Vickers hardness tester adopts unique precision design in mechanical, electrical and light source, which makes the indentation imaging clearer and measurement more accurate. The colour LCD display and high-speed 32-bit microprocessor control system are used to fully realise man-machine dialogue and automated operation. It has high testing accuracy, simple operation, high sensitivity, easy to use and stable display value. Through the motor control of the test force automatically apply, hold, unload, hardness value direct display and other functions, can meet a variety of hardness measurement requirements.

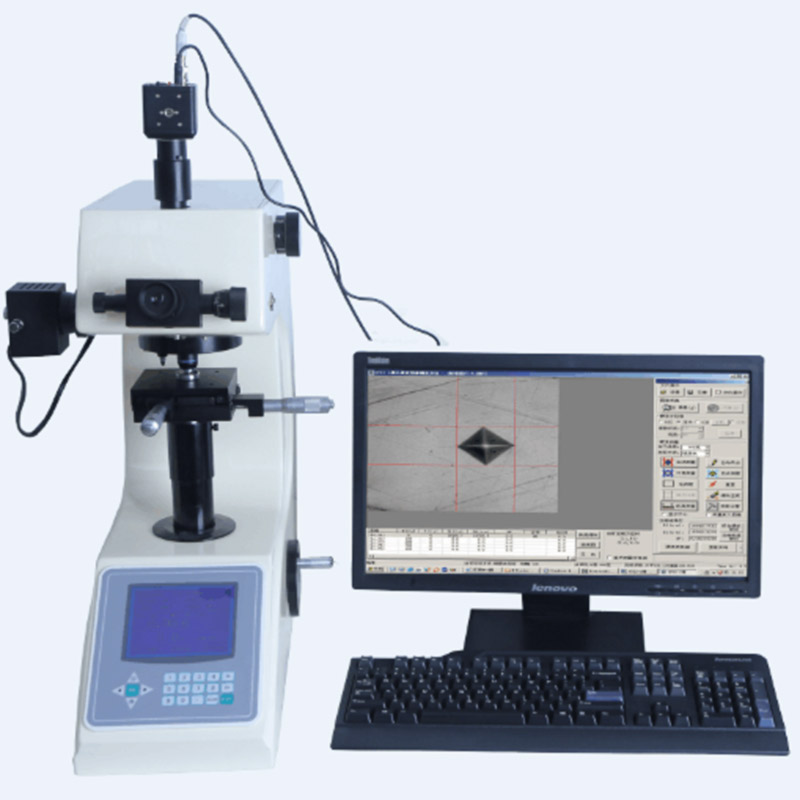

The computer is installed with a professional Vickers hardness measurement system to improve the accuracy and repeatability of the measurement. The Vickers hardness tester image analysis system connects the hardness tester to the computer through the CCD camera interface, the whole testing process can be completed through simple operation of the keyboard and mouse, easy to operate, high measurement accuracy, minimising human error and avoiding visual fatigue of the operator.

Product features:

The body of the product is formed in one piece by the casting process and is subjected to a long aging process. Compared to the piecing process, the long-term use of deformation is extremely small, and can effectively adapt to a variety of harsh environments.

Automotive baking paint, high grade lacquer, scratch resistance, still shiny as new after years of use.

an optical system designed by a senior optical engineer not only for clear images but also for use as a simple microscope with adjustable brightness, comfortable vision and non-fatiguing operation over long periods of time

equipped with an automatic turret, the operator can easily and freely switch between high and low magnification objectives to observe and measure the specimen, avoiding damage to the optical objective, indenter and test force system from human handling habits.

Optional CCD image processing system and video measuring device.

Equipped with Bluetooth module, Bluetooth printer and optional Bluetooth PC receiver for wireless printing and wireless data transmission

Accuracy in accordance with GB/T4340.2 ISO6507-2 and ASTM E384.

hardness image measurement system

The micro hardness tester is connected to the computer via the camera interface, the image is re-magnified and directly observed and measured on the computer screen, effectively reducing the operator's eye fatigue, reducing the artificial operating errors of the eyepiece system and improving the efficiency and accuracy of the test. The entire testing process can be completed by simple operation with the mouse.

The software image interface is large (800*600) and the image is clearer, which effectively reduces operational errors.

High resolution industrial camera for microscopic imaging and macro imaging. Its compact size, clear image and good imaging quality.

Convenient and practical conversion function for various hardness scales; in addition, the software has a built-in hardness and strength conversion table, which will never be lost

Powerful data reporting functions.

Test data, indentation pictures and hardness gradient graphs can be exported simultaneously for more convincing results.

When doing hardness gradient tests, the hardness gradient graph can be drawn automatically.

The header of the report, e.g. company name, title, etc. can be set and saved in advance for easy printing of the report.

The image frame can be opened partially and then enlarged, so that the measurement points can be taken more accurately and errors can be reduced.

Hardness correction function, if a point is found to be not taken correctly when measuring, it can be adjusted and corrected instantly.

The indentation image can be adjusted for contrast, brightness, etc.

Hardness calibration function: direct input of the hardness value for comparison, convenient and fast.

The image file and data file can be opened, stored and printed separately.

Ability to view data files and image files at any time; data files are typed in the form of tables, images and curves

Leading-edge indentation automatic recognition technology, reads out D1/D2 and HV values within 0.3 seconds

Automatic reading of non-mirror polished, unevenly lit, out-of-centre indentations

Automatic reading, manual reading, hardness conversion, depth hardness curve, indentation image and graphic report functions.

Original automatic reading algorithm, automatic reading of a wide range of indentations with high speed and accuracy.

High repeatability of automatic readings to meet professional user requirements.

technical parameters

|

Hardness measurement range |

5-5000HV |

|

Test force |

1.0Kgf(9.8N)、3.0Kgf(29.4N)、5.0Kgf(49.0N) |

|

|

10Kgf(98.0N)、20Kgf(196N)、30Kgf(294N) |

|

Speed of application of test force |

0.05mm/s, automatic loading and unloading of test forces |

|

Objective and indenter switching method |

Automatic switching |

|

Objective magnification |

10X (observation), 20X (measurement) |

|

Total magnification |

100×,200× |

|

Measuring range |

400μm

|

|

Indexing values |

0.01μm |

|

Number of tests stored |

99 times |

|

Test force retention time |

0-99 seconds |

|

Max. height of test piece |

200mm |

|

Distance from centre of indenter to inner wall |

130mm |

|

Power supply |

AC220V/50Hz |

|

Weight |

70Kg |

|

Dimensions |

620*330*640mm |

|

Computer |

Branded business machines (optional) |

|

Measurement software section |

|

|

Applicable operating systems |

WINDOWS7 SP1 32bit、 WINDOWS XP SP3 |

|

Digital imaging systems |

|

|

High resolution |

3 megapixels |

|

High speed acquisition |

1280X1024 resolution: 25 fps; 640X512 resolution: 79 fps. |

|

High definition |

Black and white image for better clarity |

|

Target surface size |

1/2

|

|

Automatic reading / manual reading |

|

|

Automatic reading time |

Individual indentation reading time approx. 300 ms |

|

Automatic measurement accuracy |

0.1μm |

|

Automatic measurement repeatability |

±0.8% (700HV/500gf, clear imaging) |

|

Manual readings |

Manual spotting, automatic spotting, 4-point measurement, 2 diagonal measurements |

|

Results saving/output |

|

|

Storage/output of measurement data and experimental parameters, including D1, D2, HV, X, Y, etc. |

|

|

Store/export effective hardened layer depth profile report |

|

|

Store/export images |

|

Tester Packing List

|

Name |

Specification |

|

Vickers hardness tester |

HVW-30Z |

|

Objective lens |

10X, 20X |

|

Vickers indenter |

|

|

test bench |

Large, small |

|

leveling screws |

|

|

Leveling gauges |

|

|

Micrometer eyepieces |

10X |

|

Vickers hardness blocks |

High, medium |

|

Vickers hardness image measuring system |

IS-100B |

|

Camera unit |

3 megapixels |

|

Adaptive lens interface |