Application

JBS-C Series Touch Screen Semi-automatic Impact Testing Machine is used for measuring the metal material resistance performance under dynamic load,in order to determine the material properties under dynamic load.It’s a necessary testing machine,not only used in the metallurgy,machine manufacture etcareas, but also used for the science research.

Key Features

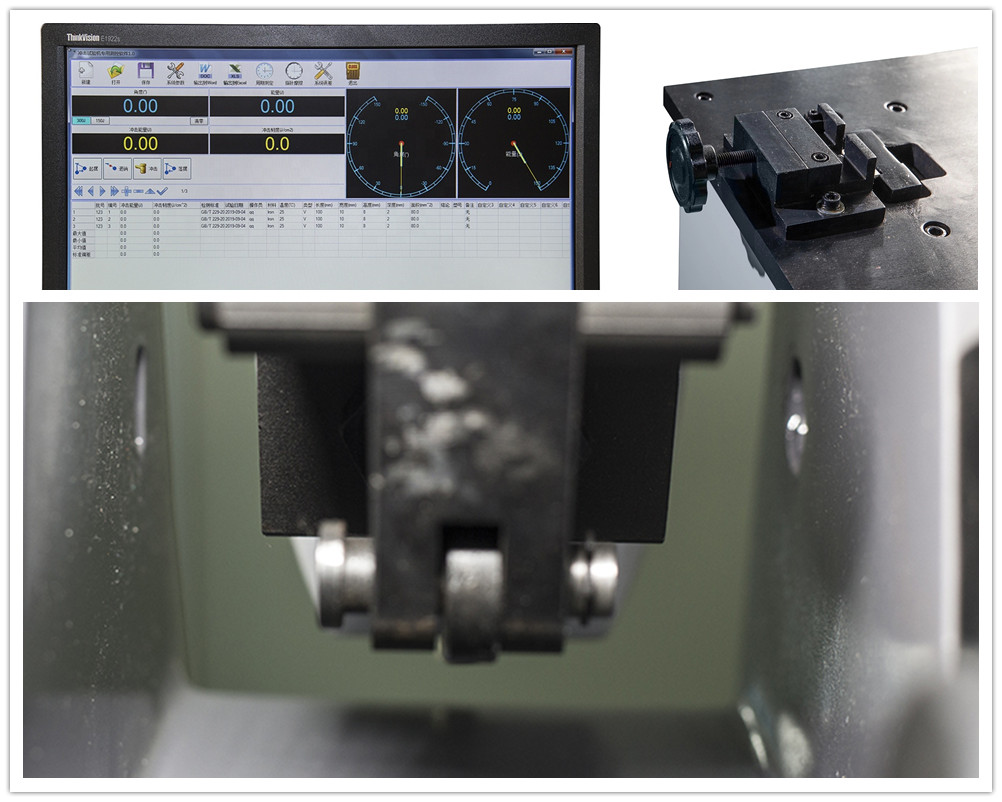

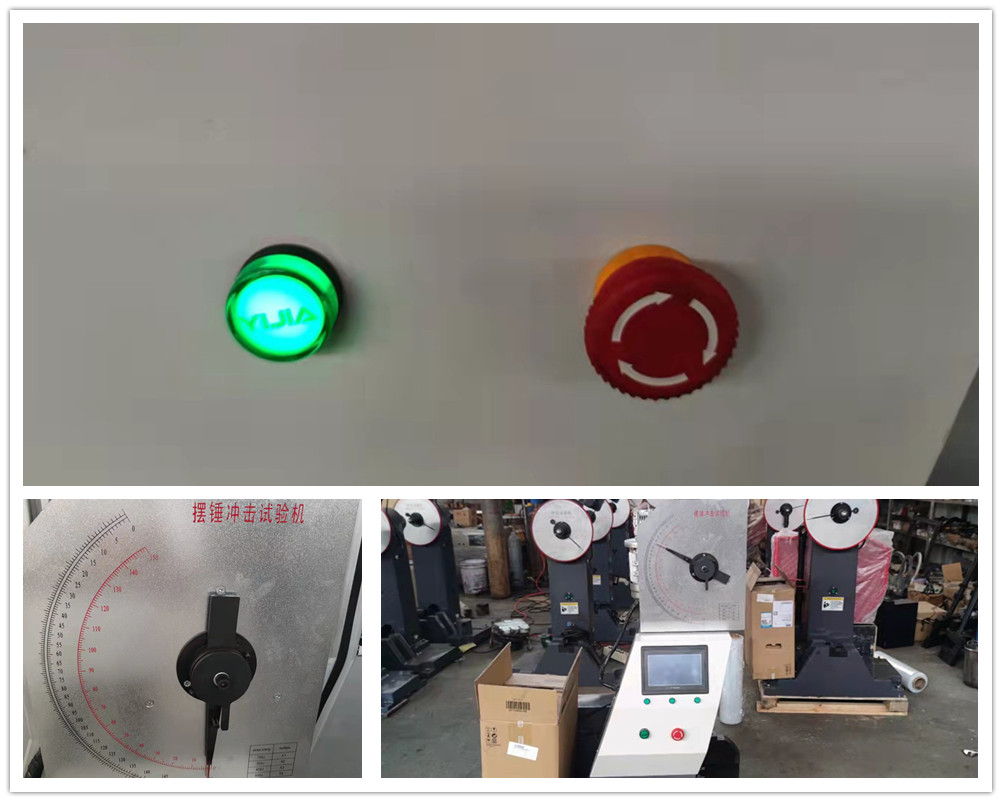

1. The equipment is simple operate with High Efficiency, Raise Pendulum, Hanging Swing, Feeding, Positioning, Shock and Temperature Adjustment Settings are controlled by a microcontroller, equipped with special feeding device automatic feeding, automatic sample face orientation. Sample baked to impact time is less than two seconds, meet the requirements of low-temperature metal Charpy impact test method.

2. It can use the remaining energy to automatic Raise Pendulum after impact the sample, prepare for the next test preparation, high efficiency.

Specification

|

Select model |

JBS-150C/300C/450C/600C/750C |

|

Maximum impact energy |

750J |

|

Effective scope of application |

30-600J(20%-80%FS) |

|

Pendulum options |

150J/300J/450J/600J/750J |

|

Pendulum advance angle |

150° |

|

The distance from the axis of the pendulum shaft to the center of the strike |

750mm |

|

Pendulum moment |

80.3848N.m ~401.9238N.m |

|

Impact velocity |

5.24m/s |

|

Anvil span |

40mm |

|

Anvil fillet radius |

R1-1.5mm |

|

Anvil inclination angle |

11°±1° |

|

Impact edge angle |

30°±1° |

|

R2 Impact Blade |

2mm±0.05mm (National standard) |

|

R8 Impact Blade |

8mm±0.05mm (American Standard) |

|

Impact blade width |

10mm-18mm |

|

Impact knife thickness |

16mm |

|

Meet the sample specifications |

10*10*55mm 7.5*10*55mm 5*10*55mm 2.5*10*55mm |

|

Machine weight |

1200Kg |

|

Rated current |

Triathlon 380V 50Hz |

|

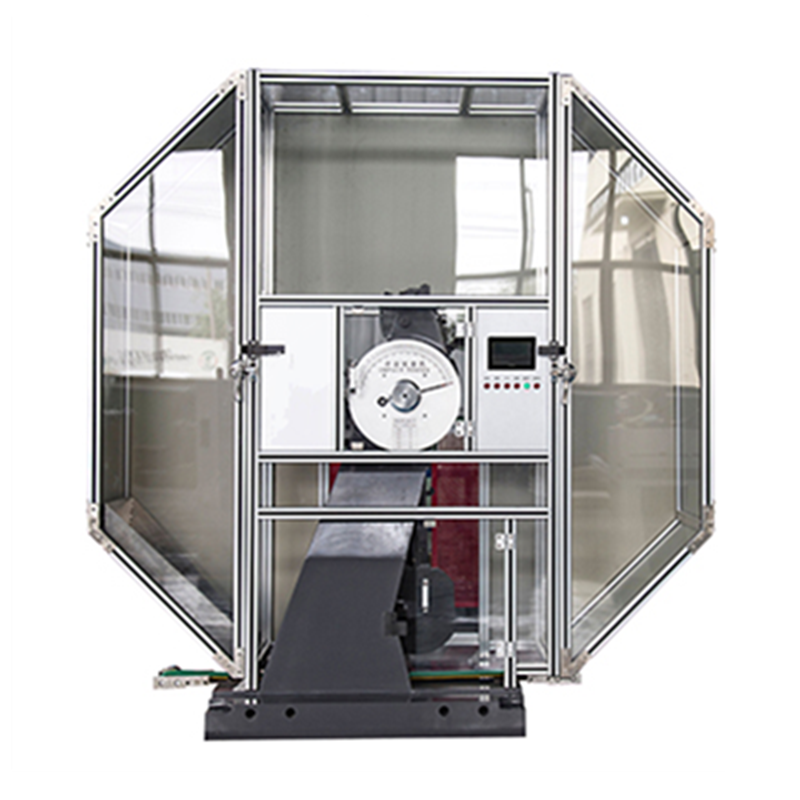

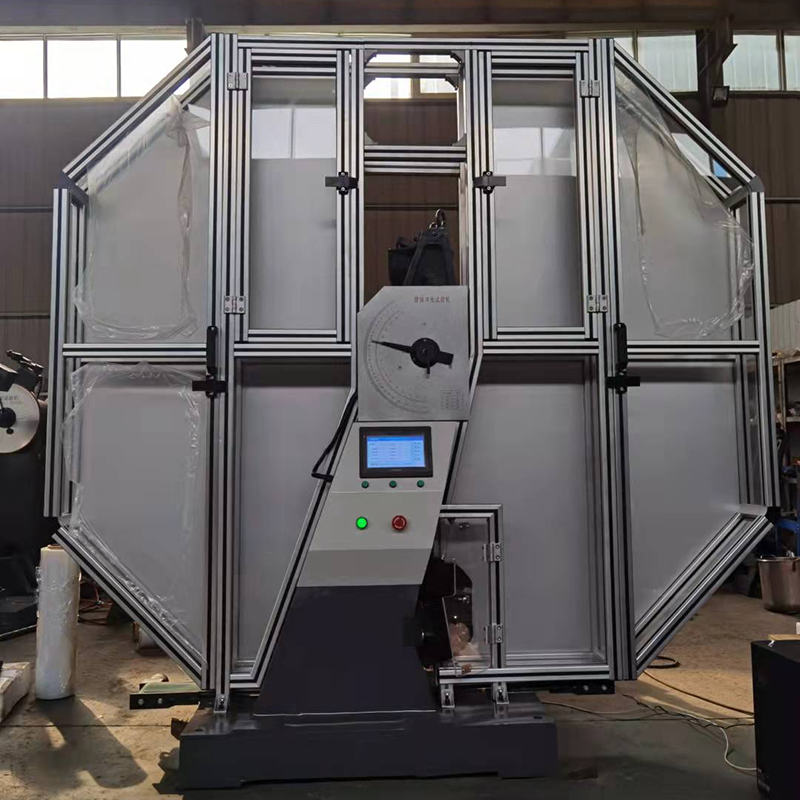

Main configuration: 1. Aluminum alloy full protection 2. Automatic sample collection 3. Digital display touch screen 4. Safety pin |

|

Standard

ASTM E23, ISO148-2006 and GB/T3038-2002, GB/229-200,ISO 138,EN10045.

Real photos