Application

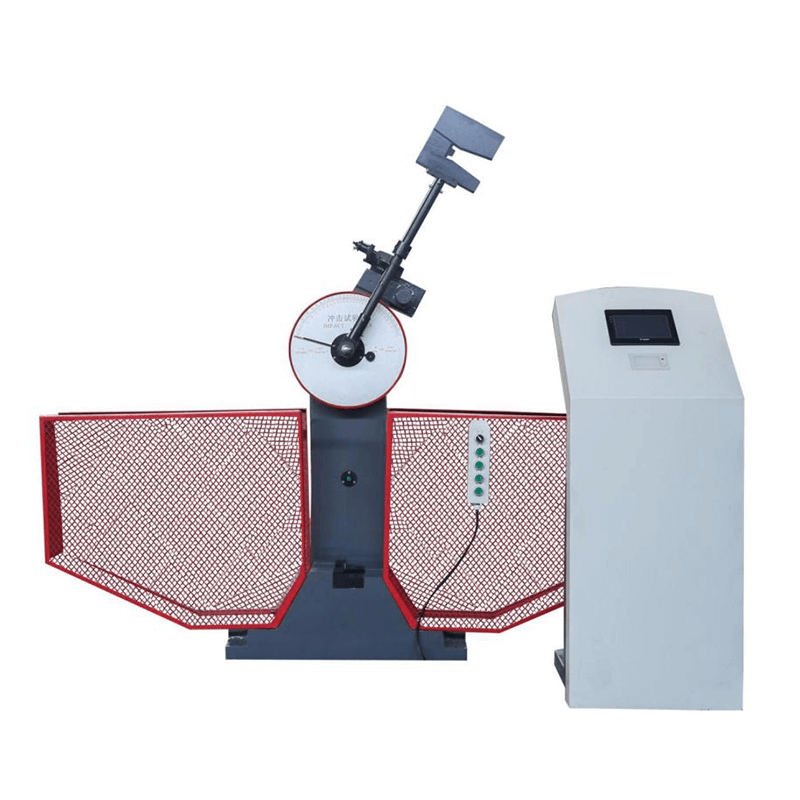

JBS-B Series Touchscreen Digital Display Semi-automatic Impact Testing Machine is mainly used to determine the anti-impact capability of ferrous metal materials with high toughness, especially for steel and iron and their alloy, under dynamic load. This series tester is operated semi-automatically, the pendulum of the machine can be raised or released automatically. Be applicable for continuing testing in different kinds of laboratories and other metallurgy industrial manufactories.

Key Features

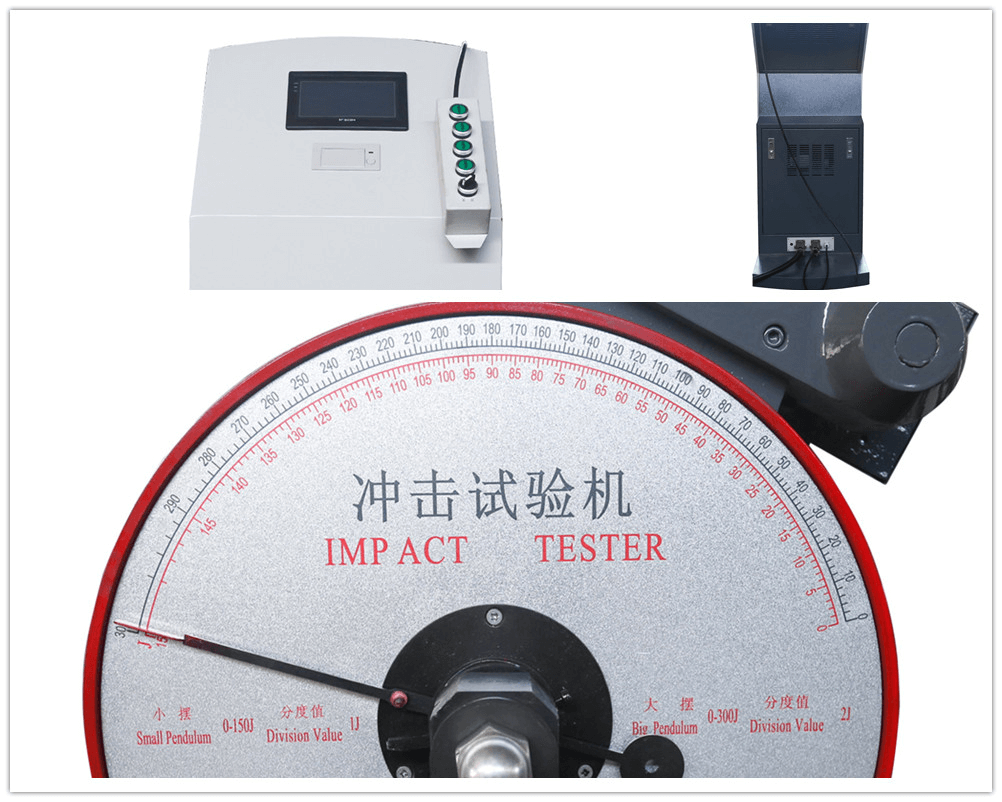

1. Pendulum rising, impact, free releasing is realized as automatically by micro control meter or remote control box.

2. Safety pin guaranties the impact action, standard protection shell to avoid any accident.

3. Pendulum will automatically rising and ready for next impact action after specimen breakout.

4. With two pendulums (big and small), LCD touching screen display the energy loss, impact tenacity, rising angle, and test average value, meantime the dial scale show test result as well.

5. Built-in micro printer to print test result.

Specification

| Model | JBS-300B | JBS-500B |

| Impact Energy | 150 J / 300 J | 250 J / 500 J |

| Control Methods | Single Chip Control | |

| Display Way | Dial Display and Digital Display | |

| The Distance Between The Pendulum Shaft And Impact Point | 750 mm | 800 mm |

| Minimum Reading Value | 1 J | 2 J |

| Impact Speed | 5.2 m/s | 5.4 m/s |

| Pre-rising Angle Of The Pendulum | 150° | |

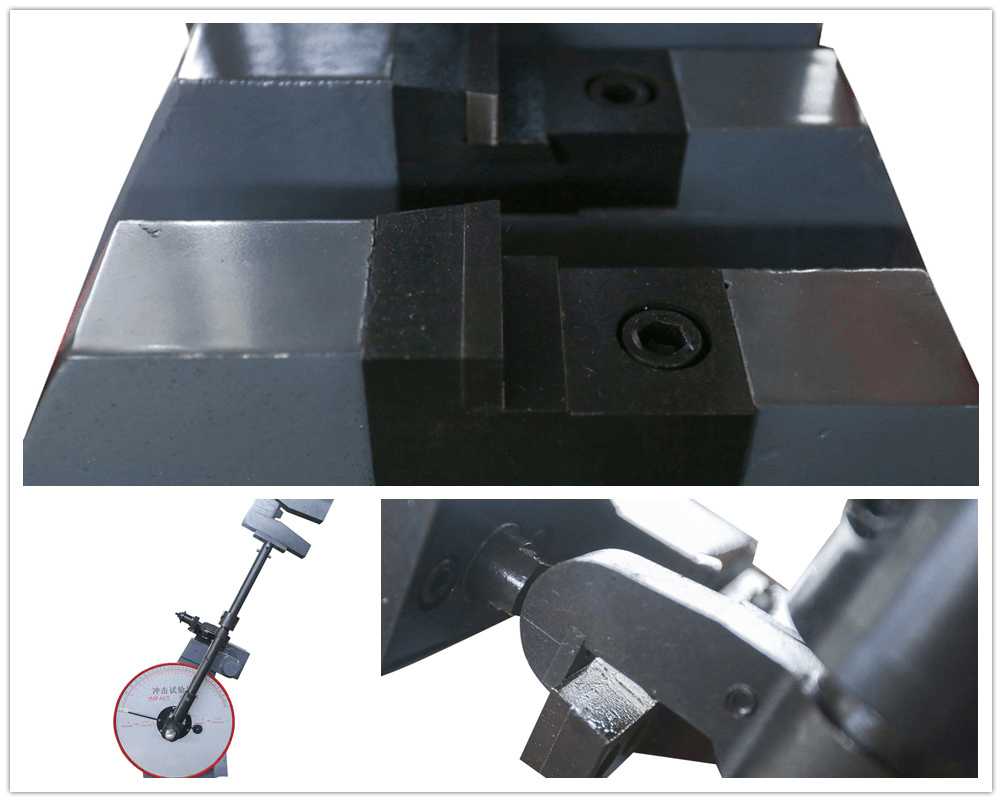

| Specimen Bearer Span | 40+0.2 mm | |

| Round Angle Of The Jaw | R 1.0~1.5 mm | |

| Round Angle Of Impact Edge | R 2.0~2.5 mm (Optional: R8±0.05 mm) | |

| Angle Accuracy | 0.1° | |

| Pendulum Torque | M=160.7695N.m 80.3848N.m | |

| Standard Specimen Dimension | 10 mm * 10(7.5 or 5) mm * 55 mm | |

| Impact Pendulum Configuration | 150 J, 1 PC; 300 J, 1 PC | 250 J, 1 PC; 500 J, 1 PC |

| Power Supply | 3phs, 380V, 50Hz | |

| Dimensions | 2124mm * 600mm * 1340mm | |

| Net Weight | 480 KG | 610 KG |

Standard

ASTM E23, ISO148-2006 and GB/T3038-2002, GB/229-2007.

Real photos