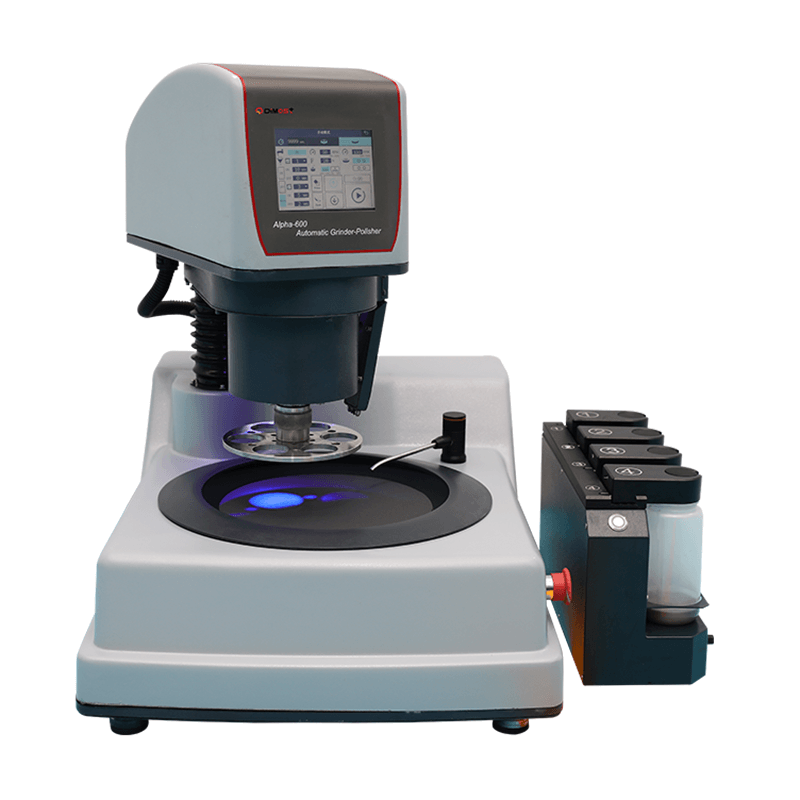

Professional China V2 Notch Cutting Machine - MP-1B Metallographic Specimen Grinding and Polishing Machine – Chengyu Detail:

Application

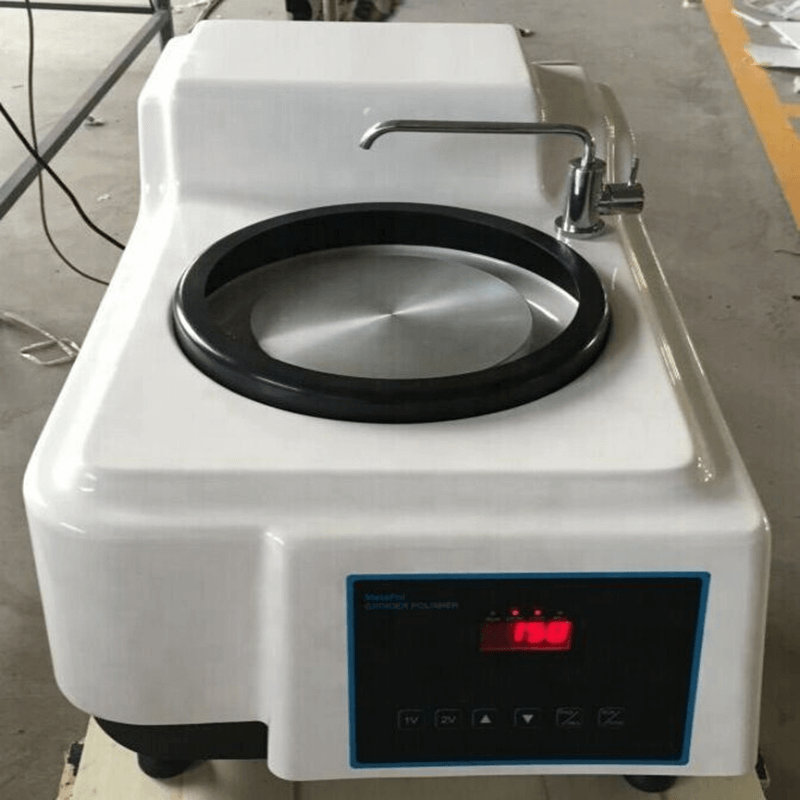

The MP-1B metallographic sample grinding and polishing machine is a frequency conversion stepless speed-regulating single-disk desktop machine, which is suitable for pre-grinding, grinding and polishing metallographic samples. This machine can not only perform light grinding, rough grinding, semi-finish grinding, and fine grinding, but also precise polishing of the samples. It is an indispensable equipment for users to make metallographic samples.

Key Features

1. Multi-usage, one machine to complete the whole process of metallographic rough grinding, fine grinding, rough polishing and fine polishing.

2. Six pieces of Φ30mm samples can be polished simultaneously.

3. PLC independent control for the grinding disc and grinding head. The grinding & polishing parameters like rotation speed, grinding & polishing time, rotation direction, water valve on/off etc. can be set and automatically saved, easy to call.

4. Large touch screen interface, convenient for parameter setting, intuitive state display and easy operation.

5. Stepless speed changing for both grinding disc and grinding head. The rotation direction is switchable between FWD & REV.

6. PLC control for water supply and grinding material dispenser.

Specification

|

Technical Parameter |

Machine Model |

|

|

MP-1B |

||

|

Structure |

Single-disk desktop |

· |

|

Diameter of grinding and polishing disc |

φ200mm |

· |

|

φ230mm or φ250mm |

O |

|

|

Rotation speed of grinding and polishing plate |

50-1000r/min |

· |

|

Turnover value |

≤2% |

· |

|

Electric motor |

YSS7124、550W |

· |

|

Operating Voltage |

220V 50HZ |

· |

|

Dimensions |

730*450*370 mm |

· |

|

Net weight |

45kg |

· |

|

Gross weight |

55kg |

· |

|

Magnetic disk |

φ200mm、φ230mm or φ250mm |

O |

|

Anti-sticking disc |

φ200mm、φ230mm or φ250mm |

|

|

Metallographic sandpaper |

320#、600#、800#、1200# etc. |

|

|

Polished flannel |

Silk velvet, canvas, woolen cloth, etc. |

|

|

Diamond polishing agent |

W0.5um、W1um、W2.5um etc. |

|

Note:“·” is standard configuration;“ O” is option

Standard

IEC60335-2-10-2008

Software

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Professional China V2 Notch Cutting Machine - MP-1B Metallographic Specimen Grinding and Polishing Machine – Chengyu , The product will supply to all over the world, such as: Istanbul, Grenada, Armenia, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.