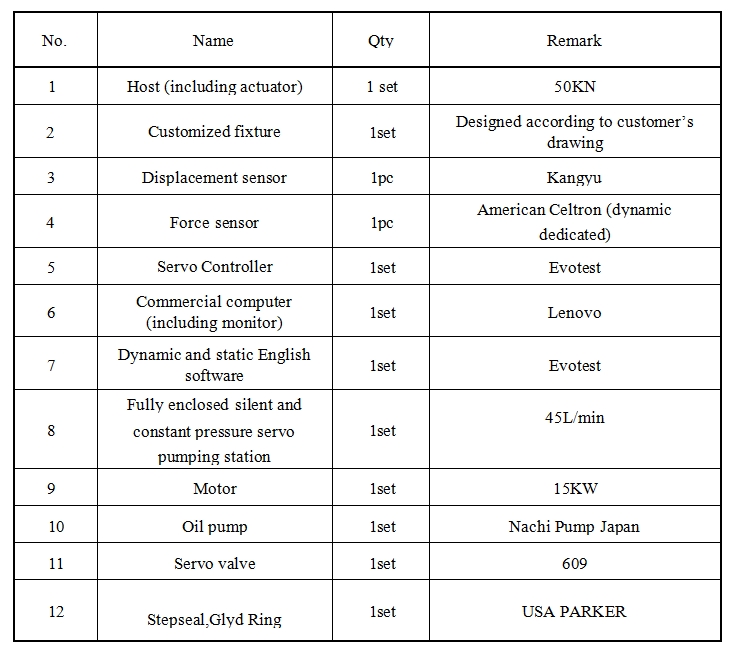

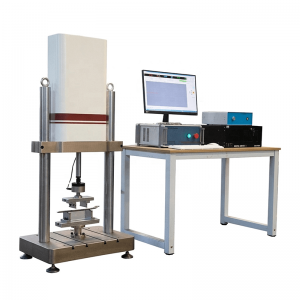

Main unit part of test system:

. 50kN high frequency and high rigidity host: 1 set;

. 21MP, 45L/min constant pressure servo pump station (oil source): 1 set;

. Evotest dynamic and static test software package: 1 set;

. Forcing the family to be specific: 1 set;

. Computer, printer: 1 set;

. Piping, accessories, tools, etc.: 1 set;

The main technical indicators of the system

1. Force

. Maximum dynamic and static test force: ±100kN;

. Effective measurement range: 2%— 100%FS in the whole process without bins;

. Static test force indication accuracy: less than ±0.5%; dynamic test force indication accuracy: less than ±1.0%;

. Average load fluctuation of test force: less than ±1%;

. Dynamic load fluctuation of test force: less than ±2%;

2. Displacement:

. The maximum displacement of the system: not less than ±75mm (the total stroke is not less than 150mm);

. Dynamic and static indication accuracy: ±0.5%FS;

3. Actuator index:

. Effective stroke of the actuator: not less than ±75mm (total stroke not less than 150mm);

. Maximum working pressure: 21MPa;

. The maximum test force is ±100KN;

. Front flange connection, installed under the workbench

4. Test frequency : 0.1 ~ 50Hz ; (Amplitude-frequency characteristics: 20kN,

±3.0mm, 17Hz)

5. Main test waveforms: sine wave, square wave, triangle wave, oblique wave, half

sine, half triangle, various combined waveforms.

6. Clamping system

One set of 4 point bending testing grips

7. Constant pressure oil source parameters:

. The constant pressure oil source adopts a double pump parallel structure, which can be controlled separately, with low energy consumption and low noise;

. Pressure: 21Mpa;

. Flow rate: 45L/min;

. Power: 380V 15kW

. The net volume of the fuel tank is 230L;