Application Field

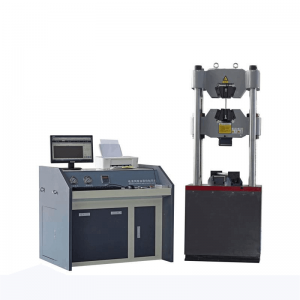

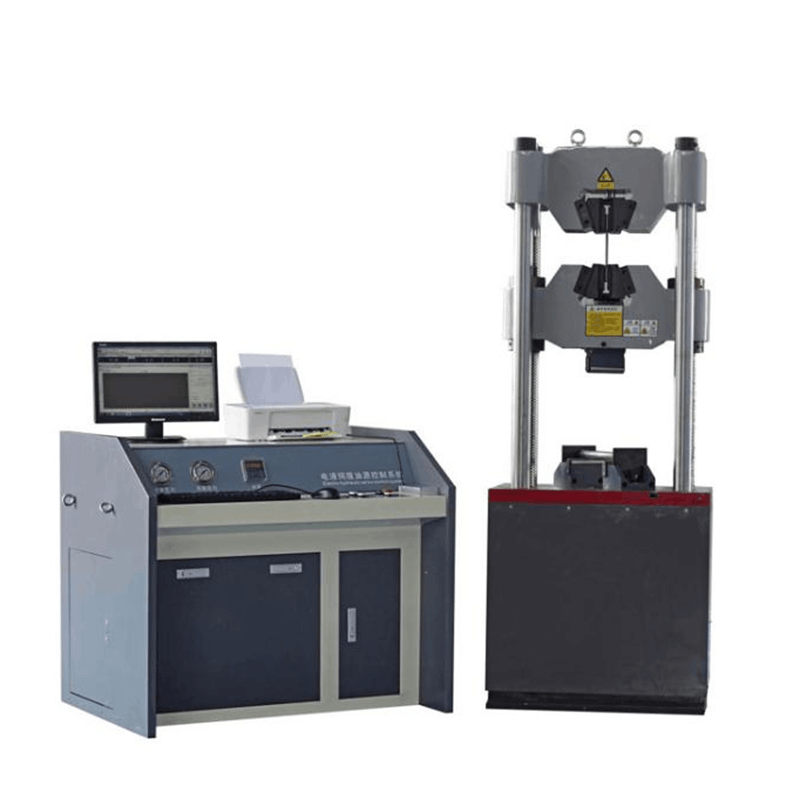

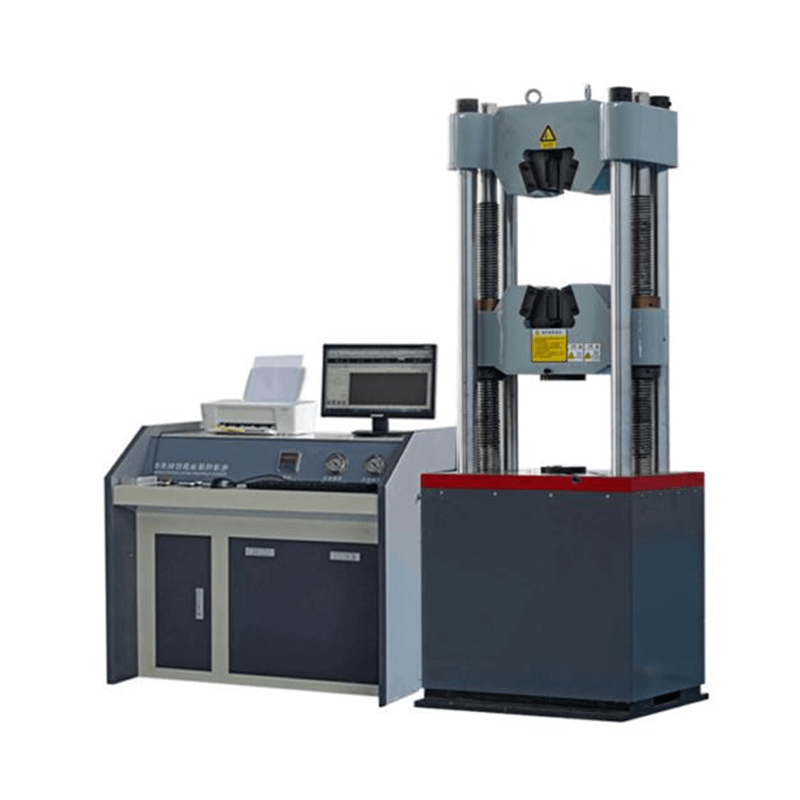

WAW hydraulic universal testing machine main machine adopts the structure of oil cylinder down type main machine, mainly used for the mechanical properties test of metal materials, non-metal materials, product parts, components, structural parts, standard parts and so on. 2.This series of testing machine can also do the material stretching, compression and bending test under the environment if it is equipped with environmental device.For example: high temperature tensile, low temperature tensile, compression and other tests.

Key Features

High Quality, High precision, Cost-effective

High rigid frame structure and precise servo motor transmission parts supply that offer stable machine operation

Suitable for Plastic, Textile, Metal, Architecture industry.

The separate design of UTM and controller make maintenance a lot easier.

With EVOTest Software, can meet capable of tensile, compression, bending test and all kind of tests.

According to the Standard

It meets the requirements of the national standard GB/T228.1-2010 "Metal Material Tensile Test Method at Room Temperature", GB/T7314-2005 "Metal Compression Test Method", and complies with the data processing of GB, ISO, ASTM, DIN and other standards. It can meet the requirements of users and the standards provided.

Transmission System

The lifting and lowering of the lower crossbeam adopts a motor driven by a reducer, a chain transmission mechanism, and a screw pair to realize the adjustment of the tension and compression space.

Hydraulic System

The hydraulic oil in the oil tank is driven by the motor to drive the high-pressure pump into the oil circuit, flows through the one-way valve, high-pressure oil filter, differential pressure valve group, and servo valve, and enters the oil cylinder. The computer sends a control signal to the servo valve to control the opening and direction of the servo valve, thereby controlling the flow into the cylinder, and realizing the control of constant velocity test force and constant velocity displacement.

|

Display Mode |

Full Computer Control and Display |

|||

|

Model |

WEW-300B |

WEW-300D |

WEW-600B |

WEW-600D |

|

Structure |

2 Columns |

4 Columns |

2 Columns |

4 Columns |

|

2 Screws |

2 Screws |

2 Screws |

2 Screws |

|

|

Max.Load Force |

300kn |

300kn |

600kn |

600kn |

|

Test Range |

2%-100%FS |

|||

|

Displacement Resolution(mm) |

0.01 |

|||

|

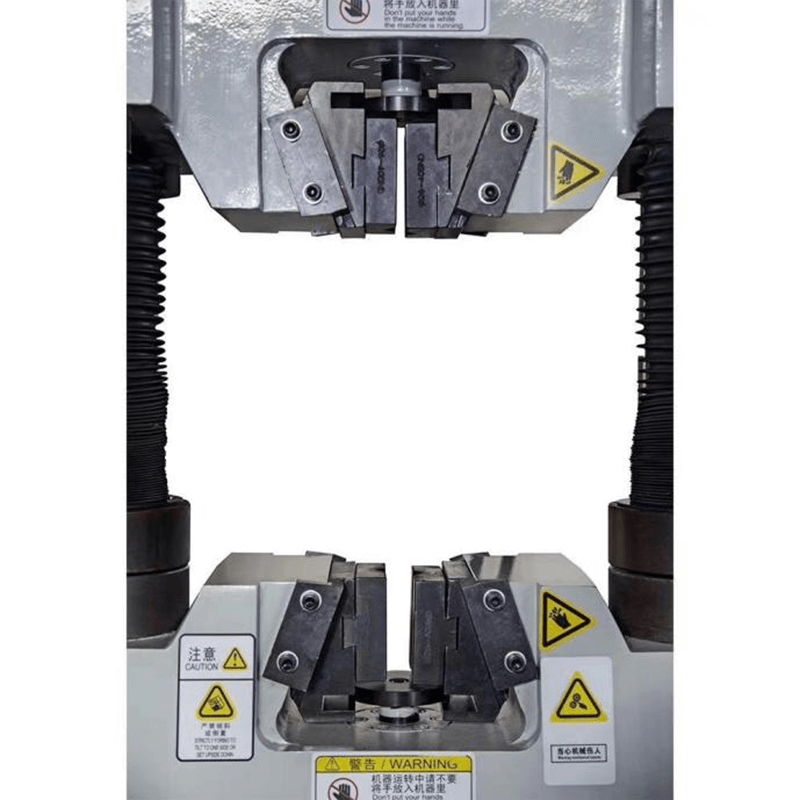

Clamping Method |

Manual clamping or Hydraulic clamping |

|||

|

Piston Stroke(Customizable)(mm) |

150 |

|||

|

Tensile Space(mm) |

580 |

|||

|

Compression Space(mm) |

500 |

|||

|

Round Specimen Clamping Range(mm) |

Φ4-32 |

Φ6-40 |

||

|

Flat Specimen Clamping Range(mm) |

0-30 |

0-40 |

||

|

Compression Plate(mm) |

Φ160 |

|||