Application

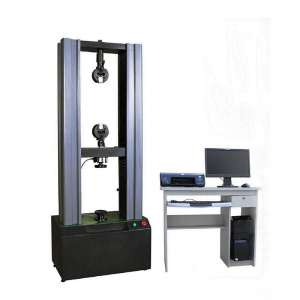

Universal tensile testing machine , also known as electronic tensile testing machine, the equipment is applicable to the measurement and analysis of mechanical performance not only metal, non-metal material, but also composite materials. It is widely used in aerospace, petrochemical, machinery manufacturing, wire and cable, textiles, fibers, plastics, rubber, ceramics, food, medicine packaging, plastic pipes, plastic doors and windows, geotextile, film, wood, paper, metal materials and manufacturing for tension, compression, bending, shearing test.

It can complete the calculation and real-time display of test parameters. Such as maximum force, maximum deformation, tensile strength, elongation at break, total elongation at maximum force, elongation at yield point, elongation after fracture, upper and lower yield strength, modulus of elasticity, force at yield point, elongation at break, yield Point elongation, breaking tensile strength, yield point tensile stress, constant elongation stress, constant force elongation (according to user specified constant force level), etc.

Specification

|

Model |

WDW-5D |

WDW-10D |

WDW-20D |

WDW-30D |

|

Maximum test force |

0.5 tons |

1 tons |

2 tons |

3 tons |

|

Test machine level |

0.5 level |

|||

|

Test force measurement range |

2%~100%FS |

|||

|

Relative error of test force indication |

Within ±1% |

|||

|

Relative error of beam displacement indication |

Within ±1 |

|||

|

Displacement resolution |

0.0001mm |

|||

|

Beam speed adjustment range |

0.05~1000 mm/min (arbitrarily adjusted) |

|||

|

Relative error of beam speed |

Within ±1% of the set value |

|||

|

Effective tensile space |

900mm standard model (can be customized) |

|||

|

Effective test width |

400mm standard model (can be customized) |

|||

|

Dimensions |

700×460×1750mm |

|||

|

Servo motor control |

0.75KW |

|||

|

power supply |

220V±10%; 50HZ; 1KW |

|||

|

Machine weight |

480Kg |

|||

|

Main configuration: 1. Industrial computer 2. A4 printer 3. A set of wedge-shaped tension clamps (including jaws) 5. A set of compression clamps Non-standard fixtures can be customized according to customer sample requirements. |

||||

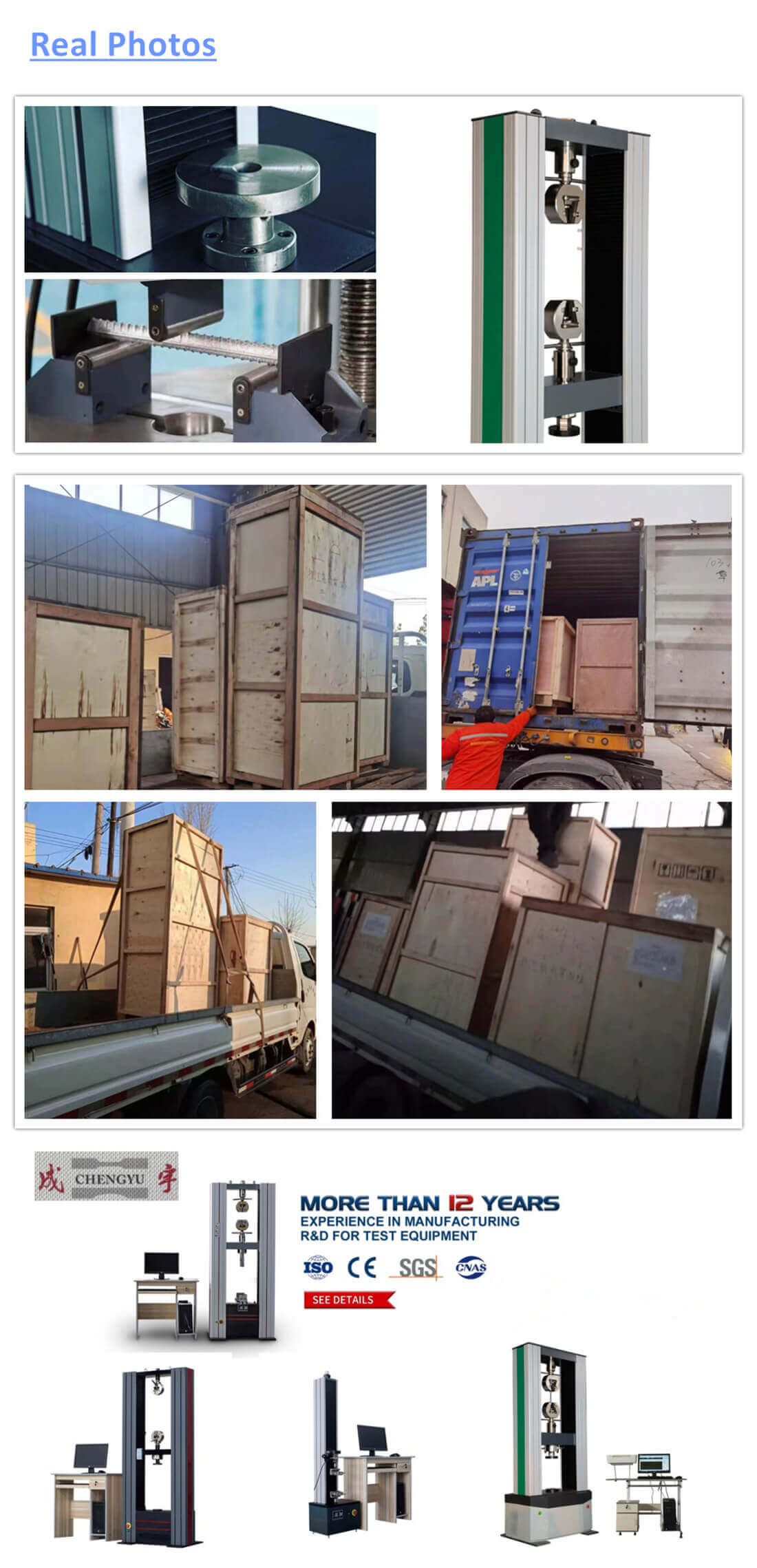

Key Features

1. Adopt floor structure, High stiffness, lower for tensile, upper for compression, upper for tensile, lower for compression, double space. The beam is step-less lifting.

2. Adopting ball screw drive, realize no clearance transmission, make sure the precision control of the test force and deformation speed.

3. The shield plate with limit mechanism used to control the beam moving range, in order to avoid sensor damaged due to the moving distance is too large.

4. The table, moving beams is made of high quality precision machining steel plate, not only reduce the vibration generated by specimen fracture, but also improve the stiffness.

5. Three columns of mandatory orientation, make the main unit rigidity much improved, to further ensure the repeatability of measurement.

6. Adopt bolt type grip installation, make the grip replace easier.

7. Adopt AC servo driver and AC servo motor, with stable performance,more reliable. Have over-current, over-voltage, over speed, overload protection device.

8. The test adopt high accuracy and digital speed system, precision decelerate structure and precision drive screw ball to realize the max range of test speed. During the testing there is lower noise and smooth operation.

9. Touch button operation, LCD display screen. It includes test methods display screen, test force display screen, test operation and result display screen and curve display screen. It’s so convenient and fast.

10. It can achieve the adjustment of crosshead’s speed when clamp the specimen.

Standard

ASTM, ISO, DIN, GB and other international standards.