Application

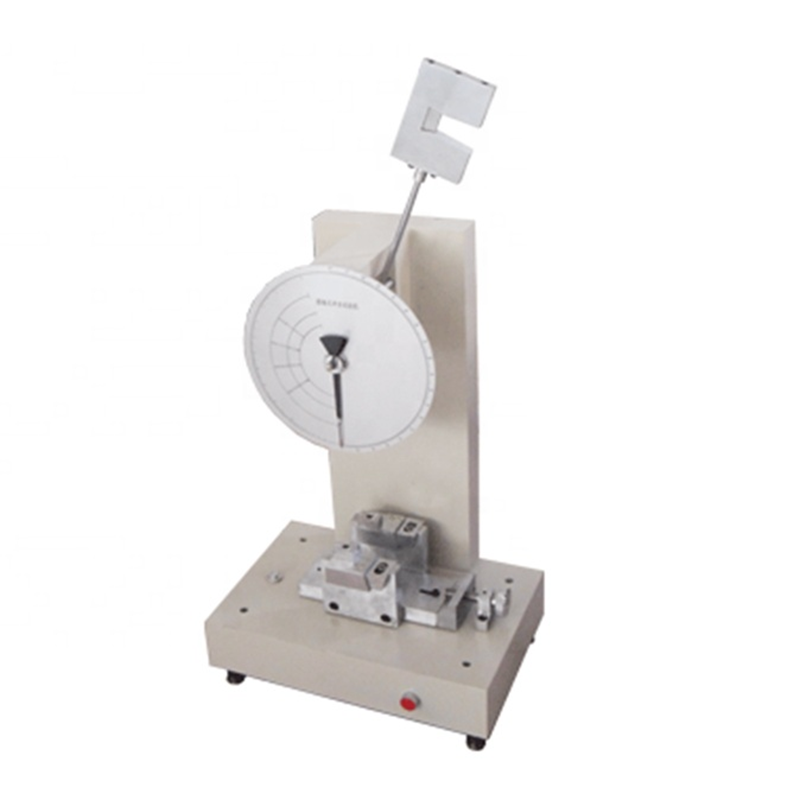

The testing machine is mainly used for the determination of the impact toughness of non-metallic materials such as rigid plastics (including plates, pipes, plastic profiles), reinforced nylon, FRP, ceramics, cast stone, and electrical insulating materials. Widely used in chemical industry, scientific research units, colleges and universities quality inspection and other departments. The instrument is a shock testing machine with simple structure, convenient operation and accurate and reliable data. Please read this instruction carefully before use. The instrument is equipped with a 10-inch full-color touch screen. The size of the sample is input. The impact strength and data are saved according to the automatically collected energy loss value. The machine is equipped with a USB output port, which can directly export data through the U disk. The U disk is imported into the PC software to edit and print the experimental report.

Key Features

(1) High quality The instrument adopts high-hardness and high-precision bearings, and adopts shaftless photoelectric sensor, which fundamentally eliminates the loss caused by friction and ensures that the friction energy loss is much smaller than the standard requirement.

(2) Intelligent tips According to the situation of the impact, the intelligent reminder of the working condition and the interaction with the experimenter from time to time ensure the success rate of the test.

Specification

|

Model |

JBS-50A |

|

Impact velocity |

3.8m/s |

|

Pendulum energy |

7.5J、15J、25J、50J |

|

Strike center distance |

380mm |

|

Pendulum raising angle |

160° |

|

Blade radius |

R=2±0.5mm |

|

Jaw radius |

R=1±0.1mm |

|

Impact angle |

30±1° |

|

Pendulum angle resolution |

0.1° |

|

Energy display resolution |

0.001J |

|

Intensity display resolution |

0.001KJ/m2 |

|

Jaw support spacing (mm) |

40、60、70、95 |

|

Dimensions (mm) |

460×330×745 |

Standard

ISO180、 GB/T1843、GB/T2611、JB/T 8761

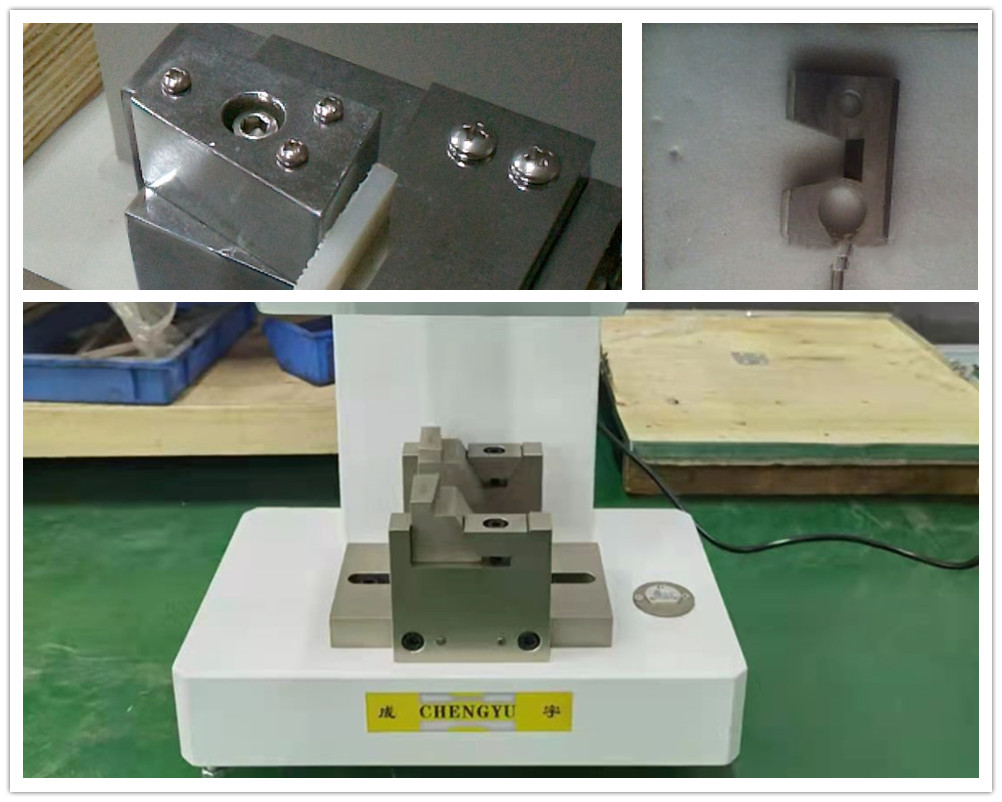

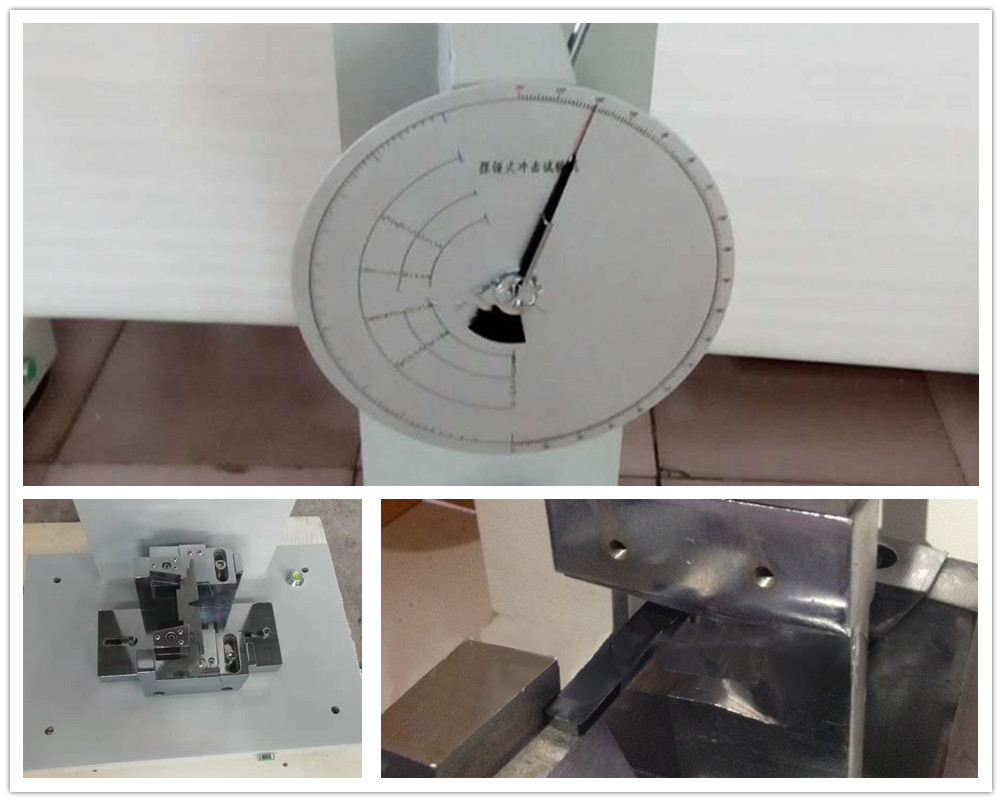

Real photos